Optical fusion splicer with core to core alignment QFS6C

Compact dimensions, high reliability and excellent splicing performances are the features of the new Qubix QFS6C splicer with 6 motors core alignment. Ideal for the use in different environments like LAN networks, FTTH infrastructures, or to terminate fiber backbones both single mode and multimode. This versatility is granted by some peculiar functions like the micrometric movement of the motors, the PAS (Profile Alignment System) core detection system and the automatic fibre recognition with reduced splice loss.

To view and download all QFS6C documents, please refer to the product page.

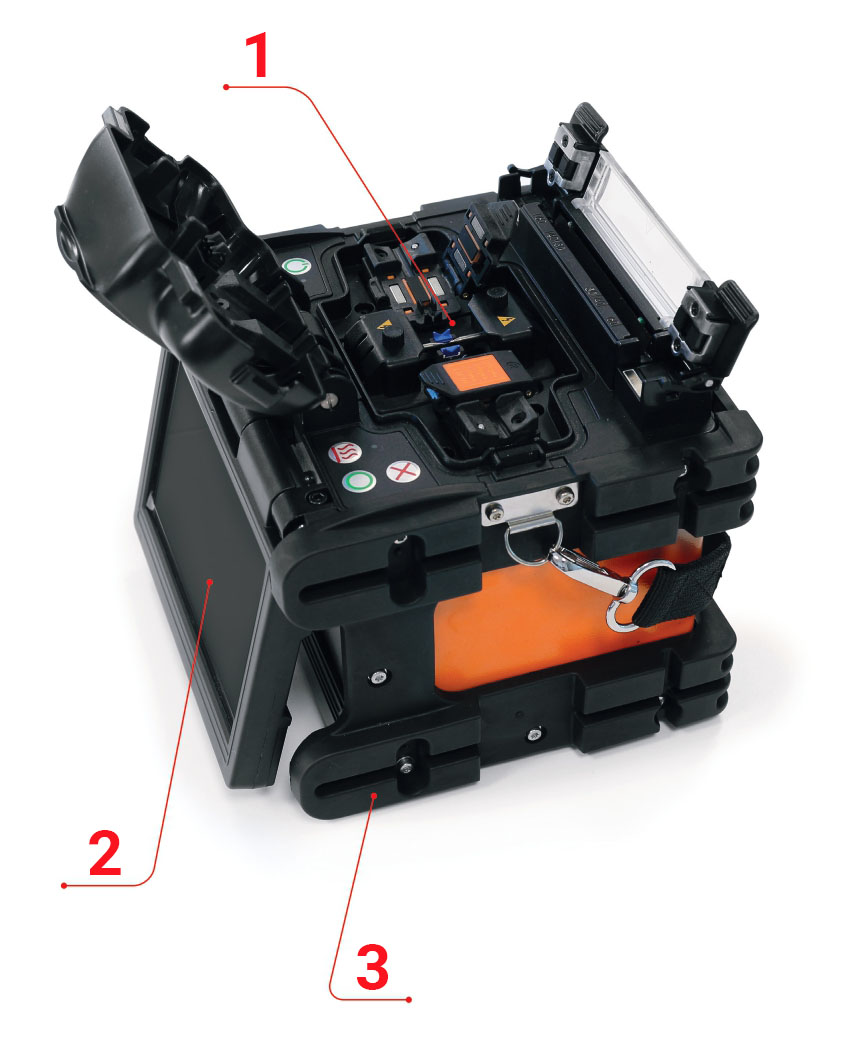

The splicer

1 – AUTOMATED PROCESSES FOR OPTIMAL RESULTS

The fusion splicer QFS6C grants splicings characterized by extremely low losses in any condition. This is achieved through automatic functions like fiber end- face inspection, auto arc positioning, temperature and pressure compensation, splice loss calculation.

2 – ORIENTABLE DISPLAY WITH AUTOFLIP

An integrated sensor of position grants the correct orientation of the 4,3’’ colour touch screen display with

autoflip and image enlargement till 500X. This way the splicer can be used either frontally or rearly.

3 – SHOCK ABSORBERS

All angles of the splicer are protected by rubber supports to absord any impact it may suffer during transport or use.

4 – COLOUR LCD DISPLAY

The colour LCD touch screen display features a simple and intuitive graphical interface. The navigation menus are available in different languages, selectable by the user during initial configuration.

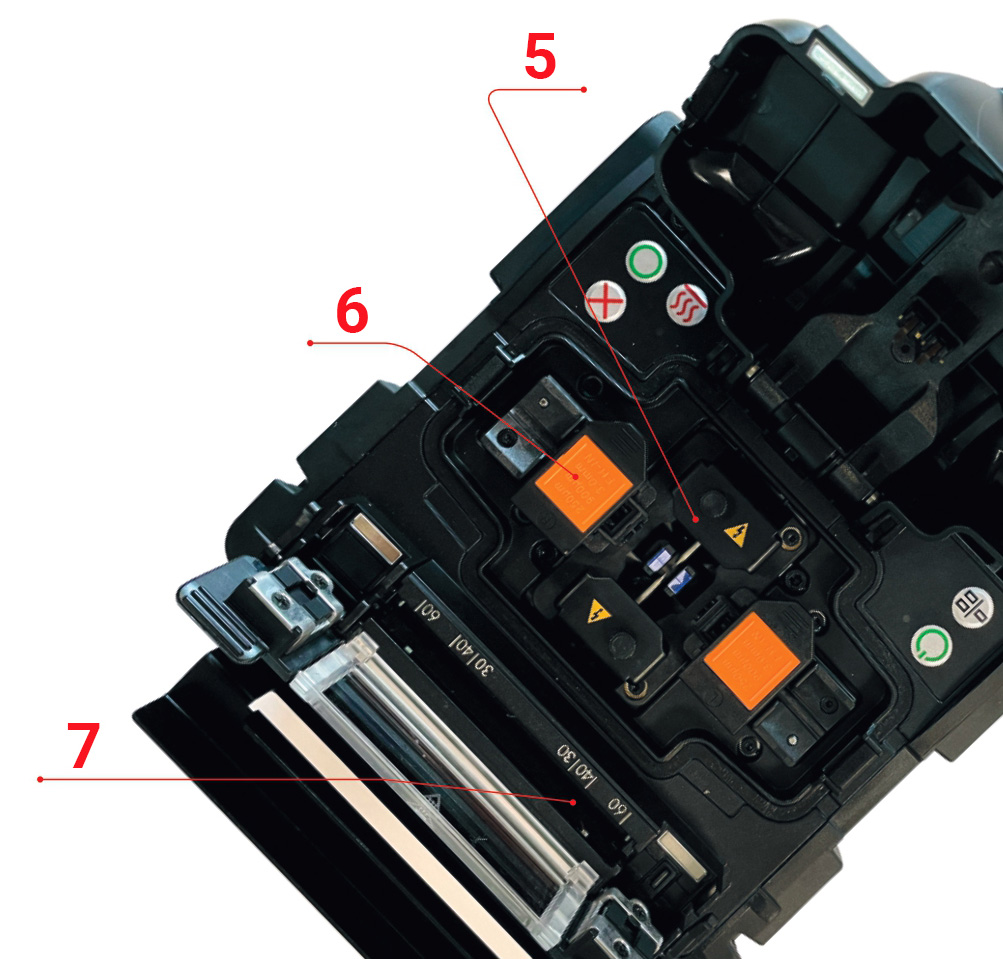

5 – FUSION ELECTRODES

With a life of up to 5000 arcs, the electrodes allow a large number of splicings. Replacement of the electrodes can be easily performed by removing the supports in a few easy steps.

6 – UNIVERSAL AND V-GROOVE FIBER HOLDERS

Equipped with magnetic universal holders, the splicer can work on fibers with 250 μm, or 900 μm in 3 mm coatings. The presence of V-grooves also allows the correct positioning of the fibers, minimizing any possible alignment fault.

7 – INTEGRATED HEATER AND HOLDERS FOR THE COOLING OF SPLICES

The heater presents some marked notches for the correct positioning of the sleeves of 30, 40 or 60 mm. It is also supplied with a semi-automatic lid. The holder for the cooling of the protection sleeves is removable and allows the positioning of more sleeves at the same time.

8 – WIND-PROOF COVER

Wind-proof cover with magnetic lock system for protection from dust, water and wind.

9 – CONTROL BUTTONS

In addition to the touch screen, the body of the splicer features control buttons so that the operator can easily activate or interrupt the splicing and heating processes.

10 – INPUT/OUTPUT PORTS

On the rear of the splicer are the charging port with LED indicators and the USB port for data transfer. There is also an additional output power port with a 3.5 mm jack for charging external devices. All ports are protected by rubber seals.

11 – BATTERY CONTAINMENT

The battery lodging is located under the orientable display, on the front of the splicer. The opening flap ensures optimal protection of the battery from dust and water splashes. The 5 LEDs on the battery make it possible to quickly check the charge level.

Fiber cleaver

12 – FIBER HOLDER

Magnetic holder for fibers and pigtails from 3 mm to 250 micron with V Groove for a precise positioning of the fiber.

13 – ROUND BLADE WITH 23 POSITIONS

The round cutting blade integrated in the Cleaver has 23 interchangeable positions. Each one can perform from 1000 to 1500 cuttings depending from the type of use and maintenance.

14 – FIBER SCRAP COLLECTOR

Automatically it contains the fiber scraps preventing any remains from getting out.

15 – CUTTING TOOL

The cutting tool is made of a sled on top of which is mounted a round blade and a magnetic pressure lid. To set the blade, there are some tightening that allow the change of position and the setting of the cutting height.

PACKAGE CONTENT

- Fusion splicer

- Cleaver with case

- USB cable for data transfer

- Cooling tray

- Fiber stripper

- Lithium battery

- Power adapter

- USB key with instruction manual and quick guide

- Carrying case

- Carrying case strap

Technical specifications

| CHARACTERISTICS | |

|---|---|

| Code | 2040380 |

| Description | QFS6C fusion splicer core-to-core |

| Alignment | Core to Core PAS type (Profile Alignment System) |

| Fiber types | SM (ITU G.652), MM (ITU G.651), DFS (ITU G.653), NZDSF (ITI G.655), BIF (ITU G.657A/B) |

| No. motors | 6 |

| Splice control | Auto and manual splicing |

| Automatic functions | Auto fiber end-face inspection, auto arc position adjustment, splice loss calculation, temperature and pressure compensation, heating |

| User interface | Graphical interface, multiple language support |

| Monitor | 4.3’’ colour LCD with touch screen and auto flip |

| Splice result | Auto splice result calculation and display (LOSS) |

| Memory | 5.000 splice records and 100 screenshots |

| Data port | USB |

| Fiber diameters | Cladding: 80 ~ 150 μm Rivestimento 100 ~ 1000 μm |

| Cleave length | ≤16 mm, minimum support length 8 mm |

| Typical splice loss | Multimode fibers G.651 ≤ 0.01 dB Singlemode fibers G.652 / G.657 ≤ 0.02 dB Singlemode fibers DSF/NZDSF/EDF ≤ 0.04 dB |

| Return loss | > 60 dB |

| Settings | Preloaded: 30 for the splicing, 6 for the heater. Free settings: 200 for the splicing and heater |

| Average splice time | ≤ 9 seconds |

| Average heating time | ≤ 25 seconds |

| Zoom | 500x on X e Y |

| Electrode life | > 5.000 splices |

| Tension test | ≥ 2 N |

| Power supply | Rechargeable lithium battery with charging leds 220V ± 10% 50 Hz |

| Battery life | > 200 splicing and heating |

| Charging time | 4 hours |

| Dimensions and weight | 125x125x135 mm – 1,9kg (battery included) |

| Working temperature | From -20 to +55 °C , humidity max 95% |

| Height | 0 ~ 5.000 mt |

| Wind speed | ≤ 15 mt/sec |